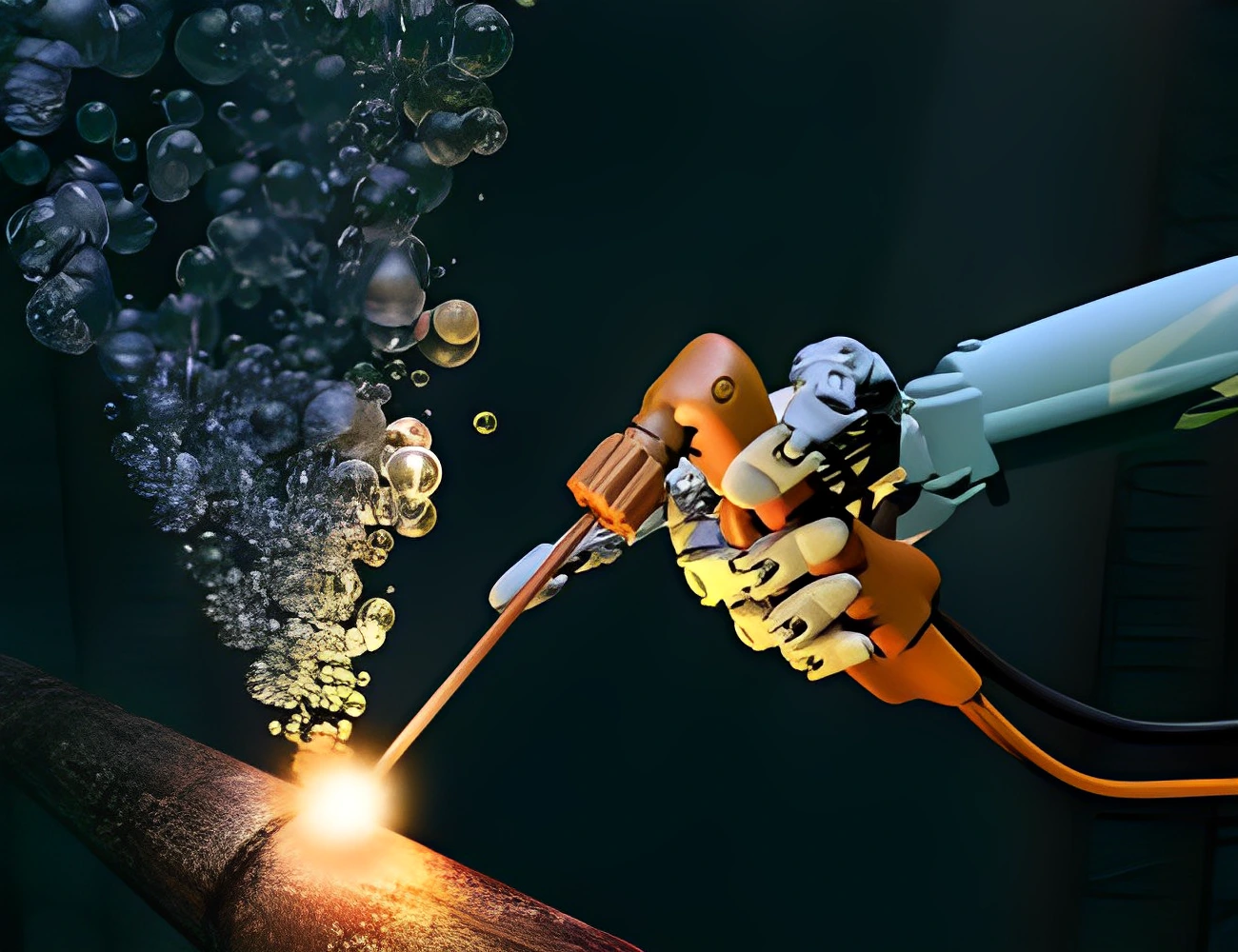

The process of underwater welding seems unbelievable.

Can you imagine electricity flowing through water and leaving the welder unscathed?

Underwater welding functions similarly to topside welding, even though the environment differs.

When you think about underwater welding, what comes to your mind?

Underwater welders take the risk, but less than you think.

Types of Underwater Welding

Two basic methods are used in underwater welding: wet and dry.

Wet welding is performed directly into the water.

Dry welding, known as hyperbaric welding, is a specially constructed dry chamber for underwater welding.

Wet welding is appreciated for its quick deployment and cost-effectiveness, whereas dry welding is preferred for its higher quality welds and safer working conditions.

Underwater Wet Welding Process

The welding spots are surrounded by water, but this does not mean they have direct water exposure in the whole process.

The welding process creates gaseous bubbles that temporarily shield the site. These bubbles comprise 70% percent hydrogen and come from the flux during melting on the electrode.

The flux will cover the welding site and protect it from water during the cooling process. However, water can still affect the weld, even with protection.

During welding, the electric arc produces significant heat and thousands of bubbles. These bubbles can be annoying and even blind the welder, making it difficult to see the site of the weld.

Underwater welding is quite challenging, so welders who can do it make good wages.

Do you want to know how much does an underwater welder make? Well, they get $38k- $300k based on their experience.

Underwater Hyperbaric welding process

Also called dry welding, hyperbaric welding offers a weld site that gets insulated from the water. The insulation gets accomplished through a barrier full of gas.

The procedure is similar to topside welding, with several exceptions. This process occurs under extreme pressure, approximately 0.7% pounds per inch or more. Pressure must increase to keep the air volume constant and set the ratio to the surrounding amount. This welding process is carried out in a pressurized underwater habitat.

The habitat might fit around the site of the weld or even expand up to one room's size. This procedure can be costly. More significant habitats are expensive and cost more money for purchasing and upkeep.

Additionally, maintenance while being used will rack up the bill because it supplies constant electricity and gas to the welder.

Underwater Welding Equipment and Gear

Every welding job is different. Welders need versatile tools that can withstand significant abuse. In marine environments, welders must understand how their tools work differently, especially underwater welding.

Diving helmet

Diving helmets are essential for welders who work underwater. These helmets have a hood that protects the welder's face and eyes from the surface while allowing them to breathe.

Welders often use the same helmet for regular diving but with an additional welding screen attached to the front for eye protection. These screens can flip down or up and are available in different shades.

There are three main types of diving helmets that underwater welders use, depending on the project they are working on:

1. Open Circuit - This standard helmet uses a non-return gas valve, side weights, an anti-fogging lens, new characteristics, and an inner cushion. The exhaled air goes into the water through the non-return valve.

2. Reclaim - This helmet works on the same principles as the open circuit but recycles the diver's exhaled gas and returns it to the system at the same pressure.

3. Free-Flow - This is a simple helmet with large transparent visors for better visibility. The diver can take it apart and put it back together using a wrench and screwdriver. It is used for shallow water and hazardous materials.

Accessories of underwater welding

In addition to the helmet, welders require necessary attachments and accessories.

Diving Knife

Just like the whip is crucial to Indiana Jones, so is the knife to the welder diver. It is essential for many situations, whether they want to cut in the project material, free themselves from entanglement, or wedge open a door. The diving knife does this job.

Umbilical cord

This lifeline supplies gas to and from the surface for the welder, ensuring a constant flow of essential gases during the welding process.

Harness

A harness is essential for maintaining the diver's buoyancy and keeping them stable while performing their work.

Compressor and gas panel

A qualified team monitors the gas gauges and maintains a steady supply of air coming to the underlying diver. Divers monitor them directly. Many employ low-pressure gas because of low maintenance and an unlimited air supply.

Bailout Gas

In emergencies, divers carry bailout gas as a secondary source of supply, typically in the form of small scuba tanks.

Knife Switch

The knife switch is not similar to the diving knife. It is utilized while using underwater electric equipment when welding. Constructed like a simple lever, it controls the electricity floor from the topside to provide power to your tools.

Diving Suit

The choice between a dry suit and a wetsuit depends on the specific requirements of the diving environment. Many commercial divers opt for dry suits due to their superior protection and climate control.

Coverall and Gloves

For additional protection, many underwater welders wear coveralls over their suits and use thick lineman gloves on top of several latex pairs to protect their hands from extreme conditions.

Respirators

Often overlooked, respirators are crucial for protecting underwater welders from toxic fumes released during the welding process. Finding a low-profile respirator that fits comfortably under the welding mask is essential to ensure proper protection.

Hands, chest, and arms

Your hands, chest, and arms are the closest to the fire line for the molten slag and sparks. There is no need to satisfy dexterity while picking the safety gear. Depending on the job, you will require a welding apron or a full welding jacket with different sleeves. Gloves are necessary for all types of welding.

Waterproof Electrodes

The electrode is a crucial part of underwater welder tools because it provides material for welding. There are many materials and sizes to select from, from the small 1/8-inch welding rods that work on mild steel to a larger 5/32 stainless steel rod.

The main difference between underwater welding and topside is the coating; marine electrodes must be extremely water-resistant. Some divers coat their electrodes, but many of them last for more hours.

They work perfectly well for depths that go up to thirty-three feet. Below that level, the pressure will cause added porosity that can damage the structure's integrity.

Water Resistant Coating

It would be better if it could hold up for long in the hostile marine environment.

High Strength Yield

Materials of better quality inside the electrode provide high-density weld that can last long. Typical diameters are 5/32 and 1/8 inches.

Underwater Stinger

When it comes to the marine stinger, less is more. They hold electrodes and are primarily manufactured from lightweight plastic, reducing the possibility of fatigue and cramps.

Underwater welders who train with particular stingers always prefer using the same type while at work, even if a newer model exists.

It would help if you stuck with what you know as a consensus. This is due to the feeling that other job sections could be more predictable.

Nonetheless, updated equipment assists the dive in being safer, having an efficient operation, and helping reduce overall costs. This equipment makes these tool types cutting edge, especially the underwater torches. An underwater stinger of high quality has the following physiognomies.

Insulated

Saltwater is a great conductor of electricity, and welder divers require all the necessary protection from this. If the stinger has good insulation, it will keep welder divers from feeling the current even at two hundred amps.

Lightweight and ergonomic

The bigger the project welding, the more the underwater welder requires a stinger that can hold for a long period.

Angled Correctly

The stinger requires the perfect notch and hole where the underwater welder can put in the electrodes. It allows for optimal use in various positions of welding and distinguishability.

Underwater Welding Machine

Current and amperage matters when it comes to the welding machine. Counter to many topside welding processes, controlling marine welding equipment works well with the control team and the divers below the boat. Immediately before the diver starts welding, they will communicate to the control team through the radio.

This provides a signal to turn underwater welding machines to the right amperage.

The required power is dependent on the electrode size. Since most welding is done on top, a few companies formulate welding machines made explicitly for underwater welding. Some need additional steps to change to an output mode safe for underwater use, like removing the coil from the internal of the machine.

These are the qualities you need to look for in the power source of underwater welding.

Stable and consistent power

The right machine does not fluctuate in amps without the knob being changed, even with long power cables; it has to maintain the best, continuous flow.

Duty Cycle

The duty cycle represents when the underwater welder can operate the underwater welding equipment at maximum power or amperage. If the machine operates at 275 amps for a sixty percent duty cycle, you can weld the full throttle for sixty minutes out of ten minutes. Other machines can work at a higher level, but the power requirements depend on the electrode type being used.

DC, not AC

In water, all welding equipment needs to get powered through direct current and not alternating current. Since direct current flows in one direction, it is the best alternative to alternating current underwater. The divers utilize negative or straight polarity that offers a long life for the electrode holder.

How to use the welding equipment rightly

Welding may produce hazardous gases to your health during the process of welding. Therefore, the welders must avoid breathing these gasses and fumes and keep the head from the fume. Additionally, you must wear clothes resistant to flames, such as a shirt and denim pants made from a woven material or a unique welding jacket. Further, it would help if you remembered not to wear sports shoes because they can smoke, resulting in a burning sensation.

The manufacturer's instructions come with all welding equipment. They contain crucial safety info and informational procedures that maximize the machine's potential; therefore, users must read, understand, and follow those safety practices carefully.

When the welder is working, the work circuit is hot to the extent that it can produce electricity. Therefore, avoiding hot parts with wet clothing and bare skin is crucial since the electric shock can result in sudden death. Other things are safely maintaining the electrode holder, welding machine, welding cable, and work clamp. While working above the floor level, people have to employ the safety of the welding equipment, like using the best equipment for protection in the event they unexpectedly fall. Always remember to replace insulation that is damaged.

Welding is applied in very many fields in the industry. Nonetheless, it will result in dangers and injuries if the users or welders need to learn how to select the right safety equipment and methods of avoiding unexpected accidents. The welder must be aware of utilizing the safety of the welding equipment.

Leave a Reply